Services

Micro Tunnelling / Pipe Jacking

Micro-tunnelling is a process that involves using a remotely controlled tunnel boring machine ranging from size 300mm to 4500mm diameter to install a string of pipes underground, in any ground conditions. In Pipesolutions, we only utilizes slurry type micro-tunneling machine where spoils are removed using water through the slurry pipes via pumps. The benefit of micro-tunneling is it minimizes the impact on the traffic and surrounding area compare to conventional open trench excavation for pipe laying, which disrupt traffic and have a negative impact on the community.

This is currently the most precise pipeline installation method. Throughout the process, line and grade are meticulously monitored and maintained. When attempting to establish a new pipeline in an area where subsurface utilities already exist, this can be critical. Micro tunnelling installations are ideal for gravity sewer construction.

Micro Tunnelling / Pipe Jacking

This is currently the most precise pipeline installation method. Throughout the process, line and grade are meticulously monitored and maintained. When attempting to establish a new pipeline in an area where subsurface utilities already exist, this can be critical. Micro tunnelling installations are ideal for gravity sewer construction.

How It Works

The sequence of works in micro-tunneling pipe installation:

Construction of an entry and exit shaft at the proposed manhole location.

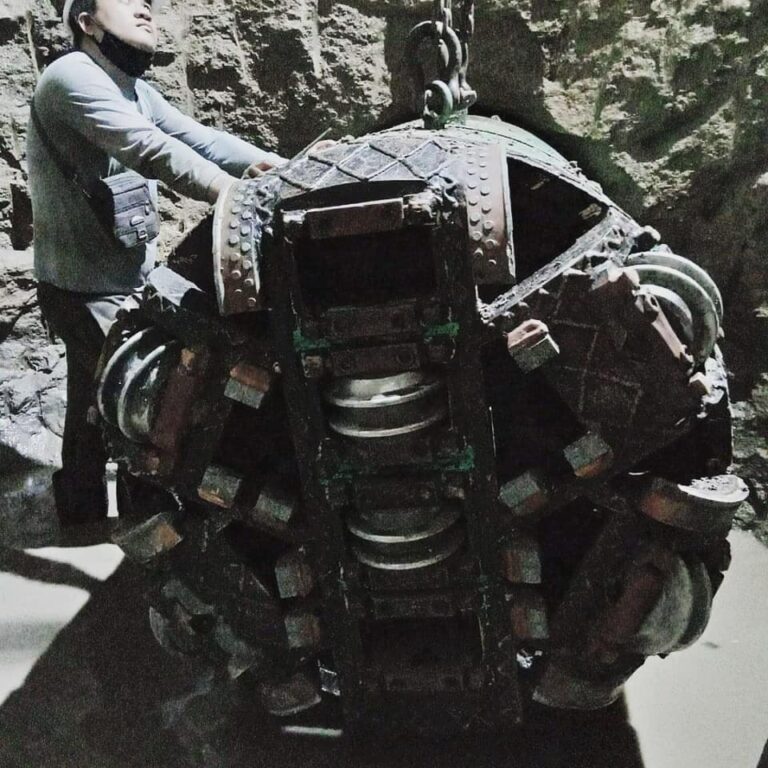

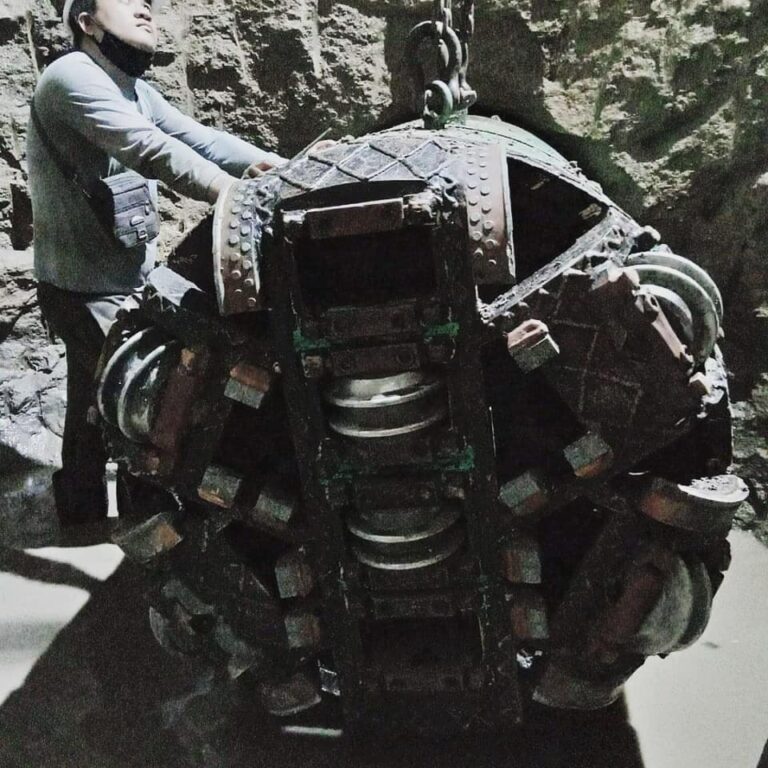

The micro-tunneling machine is then lowered in the entry shaft.

The MTBM machine will then remove the soil from its cutter face through the slurry pipes. The cutter face is rotating during this process in order loosen the earth in front of its cutter face. The loose earth will then be carried out through its slurry pipes.

The product pipe will then be pushed the MTBM machine forward.

The machine will be retrieve from the ground once it reaches the exit shaft.

Depending on design, a manhole will be constructed at the location of the exit shaft or connection to the existing manhole can be carried out.

At Pipesolution, unlike other contractors, we prefer to cover our open shafts with concrete cover during non-operation hours for safety of public.

These shafts will then be handed over to the civil contractors for manhole construction, inspection chambers, or etc.

Horizontal Directional Drilling

This trenchless pipeline installation approach is particularly environmentally friendly. It does not need a huge working area and does not interfere with other projects or urban traffic systems. It may be done at any time of the day and takes less time to complete, making it more cost effective than traditional open-trench procedures.

This method is generally use for the installation of pipeline that does not have requirements for gradient in the pipeline.

HDD technique entails the use of specialized drilling instruments that can be carefully directed around any barriers to finish any pipeline crossing. This technique is adaptable to any pipe size, length, or material that must be placed. Pipelines carrying oil, natural gas, petrochemicals, water, electricity, and network connections have all been installed using HDD.

Horizontal Directional Drilling

HDD technique entails the use of specialized drilling instruments that can be carefully directed around any barriers to finish any pipeline crossing. This technique is adaptable to any pipe size, length, or material that must be placed. Pipelines carrying oil, natural gas, petrochemicals, water, electricity, and network connections have all been installed using HDD.

How It Works

Pilot Hole Drilling a small diameter pilot hole is drilled from the ground surface using an appropriate pilot hole drilling BHA (Bottom Hole Assembly). The BHA pilot hole will be spud in at the entrance location and bored into the earth along a planned course that will traverse beneath the obstructions (rivers, lakes, channels, roads, railways, runways, existing tunnels, marsh lands, shorelines

Reaming the tiny diameter pilot hole must be widened to suit the desired product pipe as soon as the pilot hole drilling operation is done. Install a bigger diameter BHA and ream it (by rotating while pulling or pushing) along the pilot hole that has previously been drilled. Depending on the final HDD borehole diameter designed for the product pipe, this process may come in stages/sizes.

Pipe Pull Back after the expansion process is complete, the product pipe must be pulled in and attached to the HDD bore. This operation is performed by connecting the pull head to the front end of the product pipe and attaching the pull head to the retractor assembly. The pull-in assembly is then pulled into the HDD bore along with the product pipe through the HDD rig. The process is complete when the pullback assembly reaches the surface on the rig side with the product pipeline. The pull-in assembly must be disassembled from the product pipe to perform pipe connections or other subsequent work.

Line Stopping

Line Stopping

How It Works

Line Stopping Head is being inserted into the line. When the wheel reaches the bottom of the pipe, the head will pivot and roll into position.

Step 2

The Line Stopping Head has reached the bottom of the pipe and is now rolling into position. The seal will gradually be created as the sealing element touches the interior wall of the pipe.

Step 3

The head and sealing element are now in its final position and a seal has been created. The pipeline will be bled off and the modification can begin

Hot Tapping

Hot Tapping

Hot Tapping How It Works

1. Weld the fitting to the existing pipeline (Steel), screwed (cast iron) or glued (plastic) and install the valve.

2. Install the hot tap machine via permanent valve.

3. Cut the coupon and perform a hot tap a pipeline through an open valve. Special equipment holds a “coupon” for withdrawals after a hot tap surgery. Withdraw the coupon from the valve close the valve.

4. Remove the tapping machine and add a branch pipeline. Release oxygen, open the valve, new the connection works.

Closed Circuit Television Video or CCTV

A remotely operated CCTV camera can be utilized to get to the bottom of problems without having to use invasive or destructive inspection methods like digging up underground lines or removing appliances, walls, or floors to obtain access to your plumbing. Remotely operated CCTV cameras are a highly versatile tool that provide an environmentally friendly, cost-effective inspection method that can be configured to serve a variety of situations.

These CCTV cameras to detect the exact position of drain, sewer, and pipe blockages, establish what’s causing them, and then offer the simplest and most cost-effective repair option based on their findings. CCTV cameras are also very cost-effective because they are non-invasive. They can even be used for preventative maintenance to catch little problems before they become big ones.

At Pipesolution, we carried out all our installed pipeline inspection in house as we have the experience and equipment to conduct these inspections. We also provide these services to contractors or end users who wish to have new or existing pipeline to be inspected.

Closed Circuit Television Video or CCTV

Plumbing professionals use CCTV cameras to detect the exact position of drain, sewer, and pipe blockages, establish what’s causing them, and then offer the simplest and most cost-effective repair option based on their findings. CCTV cameras are also very cost-effective because they are non-invasive. They can even be used for preventative maintenance to catch little problems before they become big ones.

CCTV X3-M50-2 PUSH ROD

X3-M50 push-bar type pipeline endoscope camera can be utilized for quick video review, acknowledgment and statistics assessment for waste pipeline or pipeline organization. This pipeline endoscope camera, highlighted with straightforward activity, strong capacities, and wide relevant extension, for the most part applies to study and recognition for within pipeline in neighborhoods, private company places, extraordinary processing plants and metropolitan works, including long, restricted, or bended pipeline that can’t be gotten to with other testing instruments.

At Pipesolution, this camera is generally use to inspect for pipe sizes ranging from 100mm to 300mm diameter.

CCTV X3-M50-2 PUSH ROD

CCTV X5-HS Crawler

The X5-HS pipeline CCTV Inspection robot is based on an industrial personal computer (IPC) technology, and instead of a standard controller, it uses a laptop/ tablet. Defect photos are taken during the testing, and a testing report can be retrieved right away. Additionally, during the testing, a pipeline gradient curve can be obtained in real time to determine the sediment condition inside the pipeline. To generate the panorama image of the pipeline’s inner wall, evaluate and determine more precisely and quantitatively, a fish-eye lens is employed in conjunction with “Wincan Software for reporting” (measurement on pipe diameter, crack width and so on).

At Pipesolution, this camera is generally use for pipeline ranging from 300mm to 2000mm diameter.

CCTV X5-HS Crawler

CCTV X1- P1 Pole Camera

X1 -P1 pipeline periscope is mainly used for quick testing and diagnosis of internal conditions of industrial container or pipeline. It can record and save internal image of tested object during the testing, while it can catch the saved defect images rapidly, or input characters by keyboard, overlap-display and save them in the video during recording, defect codes can be logged in by functional key. With high degree of integration as well as portability, built-in high-performance battery is used for power supply, which is suitable for outdoor mobile work environment.

This is generally use to determine swiftly if the remote CCTV (Push rod or Crawler) can be utilize to inspect the pipeline in detail.

CCTV X1- P1 Pole Camera